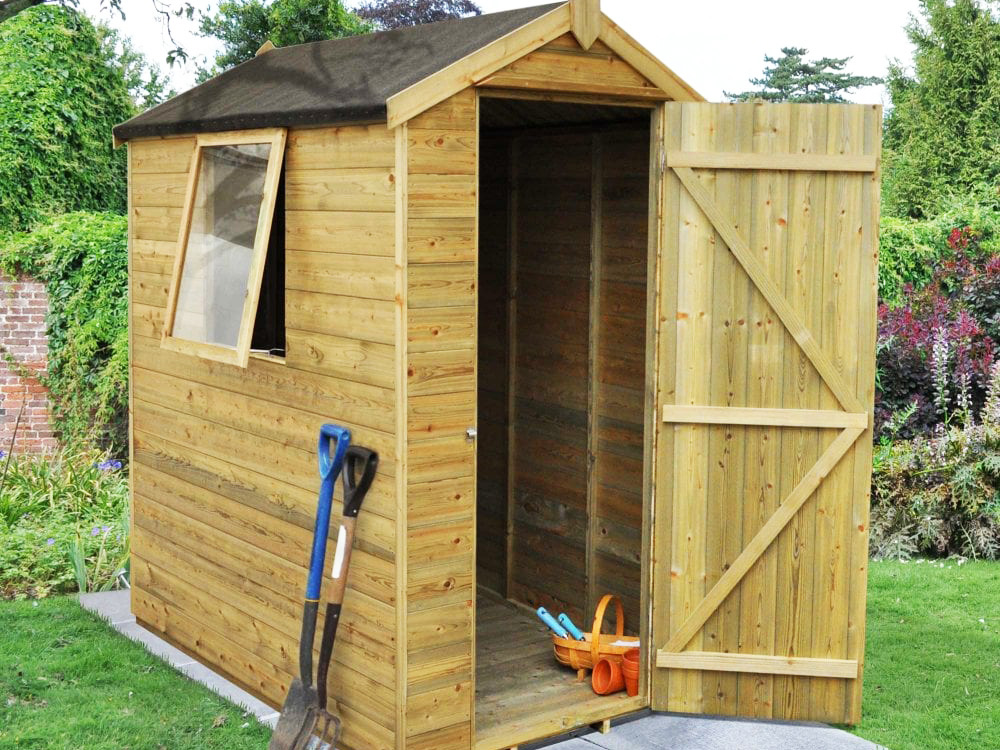

When buying a shed, you may be looking at the aesthetics, the price and its quality; however, it might be easy to overlook the build and cladding.

Whilst cladding can often be mistaken as being a seemingly minor aspect of your garden shed, it can affect the strength, price and even what you can use it for. Therefore, it’s vital to know the difference between the different styles to help you find the perfect shed for you.

Overlap, shiplap and tongue and groove are different building styles, with the wooden panels all locking together differently. Each type offers positives and negatives, so read on to find out what build is best for you…

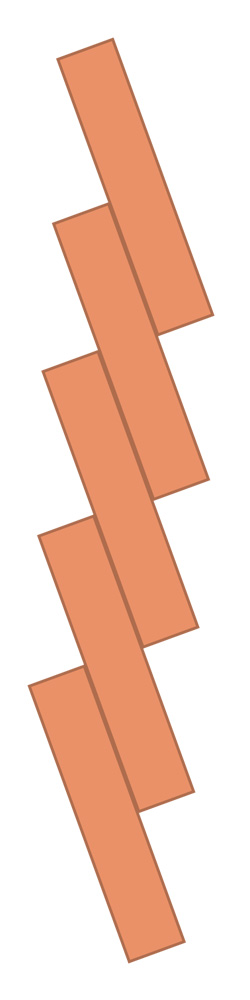

What is overlap?

Overlap is the most simple and easy to produce cladding for a wooden shed. The overlap build style features horizontal panels overlapping each other, with the bottom of each slat going over the top of the next.

The overlapping of the boards enables rainwater to run off with ease, so whilst it is watertight, the overlap design is not airtight and will, therefore, be vulnerable to draughts and damp air can enter the shed. For that reason, this type of construction is recommended for sheds that are used for storage only. If you intend to spend a lot of time in there, then you should consider a tongue and groove or a shiplap construction.

As overlap sheds are the quickest and easiest to produce, this method of construction is most commonly used on entry-level models. The overlap construction technique is tried and tested as it has been used for hundreds of years and overlap sheds are a common sight in many domestic gardens. The lower costs of this simple construction method make overlap sheds perfect for those who do not want or need to spend a lot of money on somewhere to store their garden equipment.

Advantages

+ Low construction cost

+ Ideal for storage

Disadvantages

- Susceptible to draughts

- Cannot attach shelving to the walls

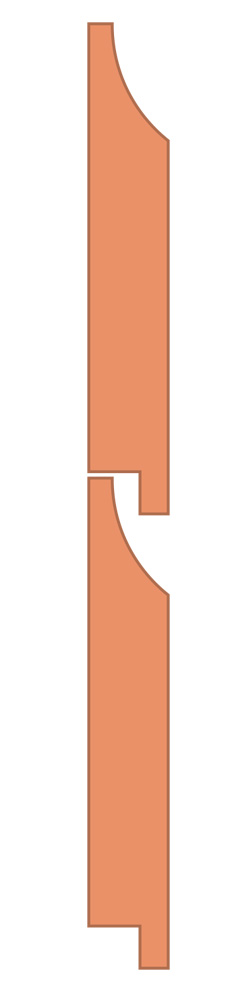

What is shiplap?

Shiplap cladding consists of wooden panels that overlap in such a way that they create a flat surface that is much more weather resistant than the overlap construction method described above. Each wooden board has overlapping lips that interlock, allowing water to run off whilst also providing better protection against draughts.

Shiplap cladding consists of wooden panels that overlap in such a way that they create a flat surface that is much more weather resistant than the overlap construction method described above. Each wooden board has overlapping lips that interlock, allowing water to run off whilst also providing better protection against draughts.

Shiplap cladding is more expensive to produce than overlap, therefore, sheds with this cladding do come with a higher price tag, however the extra protection from the elements and the extra security and visual appeal they provide make it the most preferred construction method for modern garden sheds. The construction is stronger, more weather resistant and creates a more visually appealing shed that is less susceptible to rot and warping.

The shiplap cladding is suited to those who will regularly be using their garden shed as a workshop, however, if you just need storage space, the overlap is more than sufficient.

Advantages

+ Good weather resistance

+ Neat appearance

Disadvantages

- More expensive than overlap

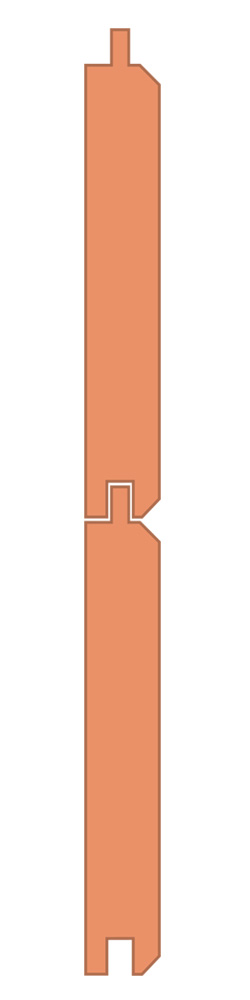

What is tongue and groove?

Tongue and groove is the most superior type of cladding used in the construction of a wooden shed. The tongue and groove construction technique is more likely to be used for larger sheds and other large wooden garden buildings. The cladding boards are created from planks of wood that slot into each other, interlocking and leaving no gaps. Due to this, the structure is extremely strong and durable and creates a shed with flat walls and an attractive appearance.

It is the most secure and weather resistant of the three constructions types, as the interlocking design means that there is no concern for moisture and draughts getting into the shed, as the tight seal will protect your shed from the elements.

Factoring in the strength, durability, weather resistant properties and it being the most time-consuming to manufacture, you can expect this construction type to be at a higher price due to the quality of the product.

Advantages

+ Excellent weather resistance

+ Neat appearance

+ Strong construction

Disadvantages

- High construction cost

Dip treatment vs pressure treatment

When it comes to choosing the perfect garden shed for you, not only do you need to be aware of the pros and cons of the cladding, it’s also vital to be aware of the treatment that your wood has had, so you can look after it accordingly. The two different types of treatment are dip treatment and pressure treated.

Dip Treated

Dip treatment is known to be one of the most common ways of applying preservatives and is exactly what it sounds like. With this technique, wood panels are dipped into a bath of treatment for a period of time. They are then taken out and left to dry.

Dip treated sheds are typically the cheaper option, due to the process taking less time and being simpler.

The problem with the dip treatment process is that it will only cover the exterior of the panels and it will not soak through into the centre. As it’s only a surface treatment, it will wear off over time, leaving your garden shed vulnerable to the elements and open to damage and rotting. Due to this, the treatment needs to be reapplied regularly and it needs more maintenance than pressure-treated structures to ensure it is protected.

Another factor that you should be aware of when purchasing a dip treated garden shed is that the structure must be raised off the ground at all times. A base is required, as this prevents unwanted damp and moisture getting into the wood and causing decay and damage to your garden shed.

Pressure Treated

Pressure treatment is a preservative process that enhances the timber’s protection. The process includes placing the timber in a vacuum chamber, which removes all the air from the cells in the timber. Once this has been completed, the vacuum will force chemical preservatives into the wood. Unlike drip treatment, this process will treat every inch of the wood and not just the surface layers.

After the initial pressure-treatment process, your garden shed will have a natural greenish tint to it, which is residue from the treatment. After a time, this will gradually fade and you will be left with a natural finish that blends into your garden.

The powerful preservatives used in the pressure treating process have anti-fungal and anti-insect properties that penetrate deep into the wood to protect it from environmental decay. It also creates a shield around your garden shed, strongly protecting it from the elements and ensuring it has a long life span.

Pressure treatment is known to be a more effective treatment and it needs little maintenance after the first process. Although it may be the most expensive option out of the two, it’s also the most cost-effective, as you don’t have to worry about damage, rotting or having to spend time and money on maintaining it.

Garden Oasis has a range of garden sheds in the different build styles and wood treatments. Browse now to find the best option for you.

Then select "Add to Home Screen"

Then select "Add to Home Screen"